FAQS

We get random questions about the capabilities of the team. The content below should help answer the most frequently asked questions.

Topics

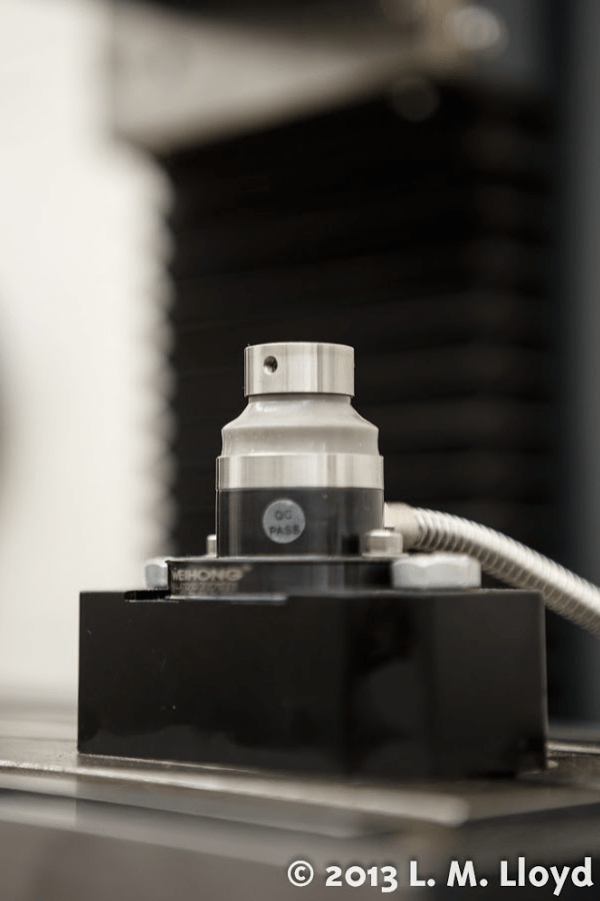

We have a couple of little robots to mill a variety of materials. Our small CNC mill is a Roland Modela and we have a larger mill for larger, more precise work. The large mill is capable of very tight, small tolerances.

Why yes, we do! We use 3D printers from FormLabs. The printers from FormLabs provide consistent results with the lowest amount of striation in the prints.

Our cutter can cut paper, stiffened fabric, vinyl and some thin leathers. We make a lot of stickers to share with people we like and make masks for painting.

Yep! Bet you didn’t know sewing machines could be computer controlled, huh? We use a Pfaff embroidery machine to create precision designs in thread, on fabric.

That is true! We have both vacuum and pressure casting space for resin, rubber or other materials intended for casting – like foam. We make molds with a 3D printer or milling machine then cast by hand or develop processes to speed things up.

We have a few really nice digital cameras and small GoPros with a simple sound and LED lighting set up that moves around the studio with us.

We also have screen printing and sewing capabilities – we don’t do big runs of those materials but we can make prototypes and small runs of screen prints and sewn objects.

We use primarily Adobe Creative Cloud applications for our 2D work. It also depends on who we are working with and if other software is needed, we are usually happy to accommodate different software packages if they are readily available.

Depending on which team member is making something in 3D, there are a few software packages in use. We use primarily Maya, Inventor and Zbrush along with Fusion 360 on occasion. Our milling and 3D printing robots have their own software to compliment their work.